500 Abarth Intake Manifold made with MJF 3D Printing in PA12

The inclination for experimentation and a strong interest in technological innovation have driven DMZ Engineering to develop projects related to 3D printing applied to the racing world. The initial results of these studies culminated in the production of an intake manifold for the 1.4 liters T-Jet engine, printed using MJF technology, which revolutionizes the market for these components. In fact, this is the first worldwide application of a structural engine component of a car made using MJF 3D printing technology.

This manufacturing method allows for the creation of any geometric shape, thus optimizing the fluid dynamics of the engine’s charge exchange system. The performance achieved by the developed product and its presentation at the MECSPE fair attracted the attention of several car manufacturers and, notably, the technology owner, HP Inc, which requested us to present our case study in their webinar (https://reinvent.hp.com/it-it-3dprint-eventi-italia#Seminari-registrati).

Hybrid Aluminum/PA12 Intercooler with Turning Vane Technology

The collaboration with HP and our partner Treddy continued with the development of other racing applications such as the Intercooler with Turning Vane Technology. The creation of the inlet and outlet tanks using MJF 3D printing made it possible to insert a series of flow deflectors inside them, which, starting from the inlet section, reach the interface section with the radiator mass, optimizing the distribution of the airflow over the entire heat exchange surface.

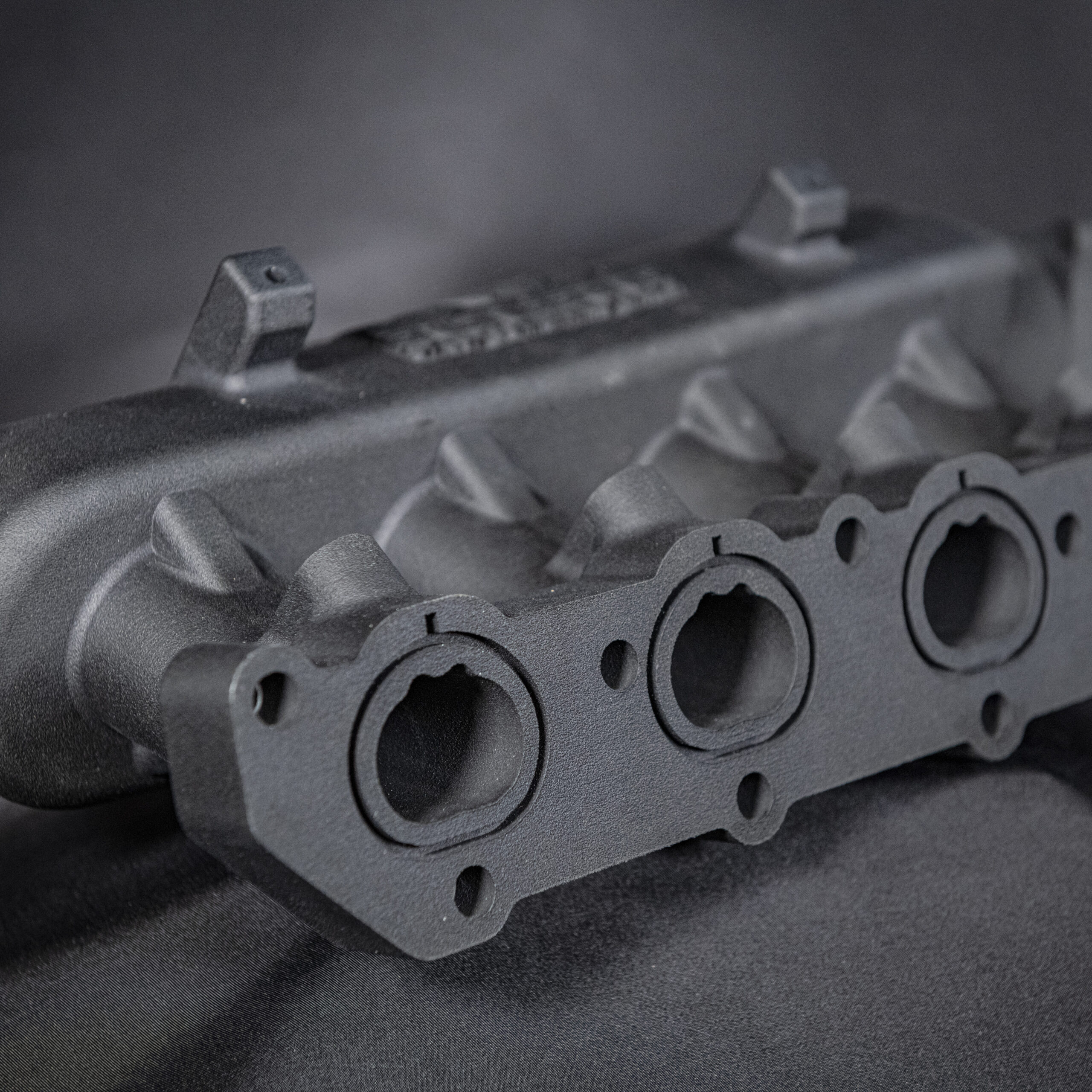

124 Abarth Intake Manifold made with MJF 3D Printing

Following the footsteps of the intake manifold designed for the 500 Abarth, DMZ Engineering is completing validation tests for a new airbox for the second car produced by Abarth. The project is in its final stages and will soon be ready for commercialization.

Intake Manifold for VAG Engines made with MJF 3D Printing

The development of intake manifolds is also extended to the cars of the VAG group. The product development is currently in the stages of structural and CFD simulation. This application is mechanically much more extreme compared to the same component produced for Stellantis group engines, as the turbo operating pressures are much higher than those of the smaller T-Jet and MultiAir engines.

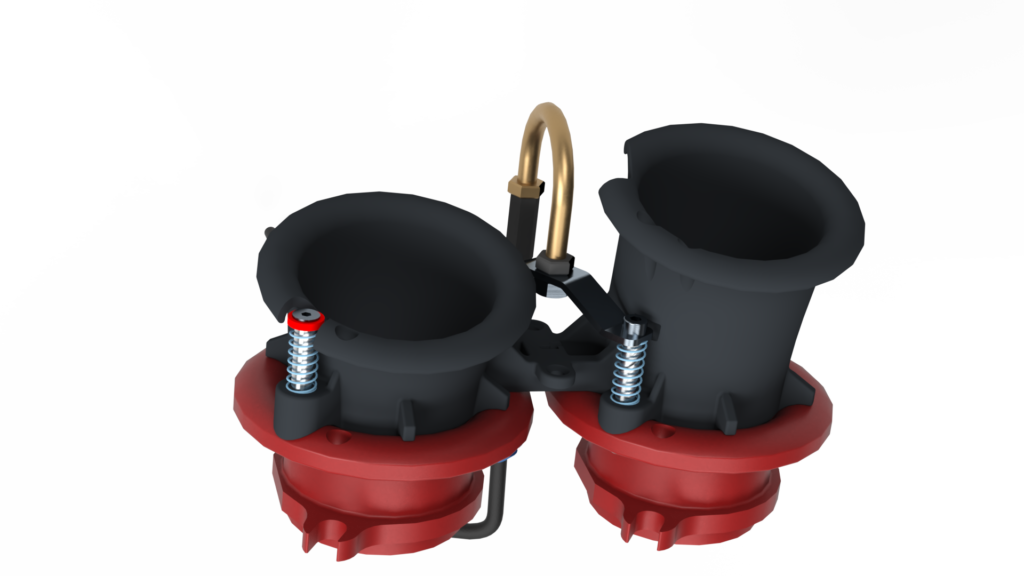

Variable Geometry Intake Cones for Aprilia RS 660

A variable geometry intake system developed in collaboration with Gabro Racing for the Aprilia RS 660. The variation in the length of the intake cones, printed with MJF technology, is achieved through an electromagnetic actuator controlled by the engine control unit. The system significantly improves the torque and power delivered by the engine across the entire operating range.

Exhaust Manifold for Stellantis Group T-Jet Engines Using Metal Sintering

Interest in the world of Additive Manufacturing has led to the development of exhaust manifold applications. A first prototype of an exhaust manifold for the 1.4 T-Jet engine, made using technology developed by Meltio, is currently being tested on a vehicle. This is the first worldwide application of an exhaust manifold for road use made with 3D metal printing. In collaboration with Meltio, DMZ Engineering is testing the thermal, mechanical, and fatigue resistance of components made with this innovative technology.

Successful test results will allow the use of this technology to create extremely complex geometries for optimizing exhaust flows in a combustion engine, surpassing the geometric limits of current technologies in use. The project has been extended to SLM technology, with the participation of Nikon SLM, with which we are developing a first application of our product made using this innovative technology.

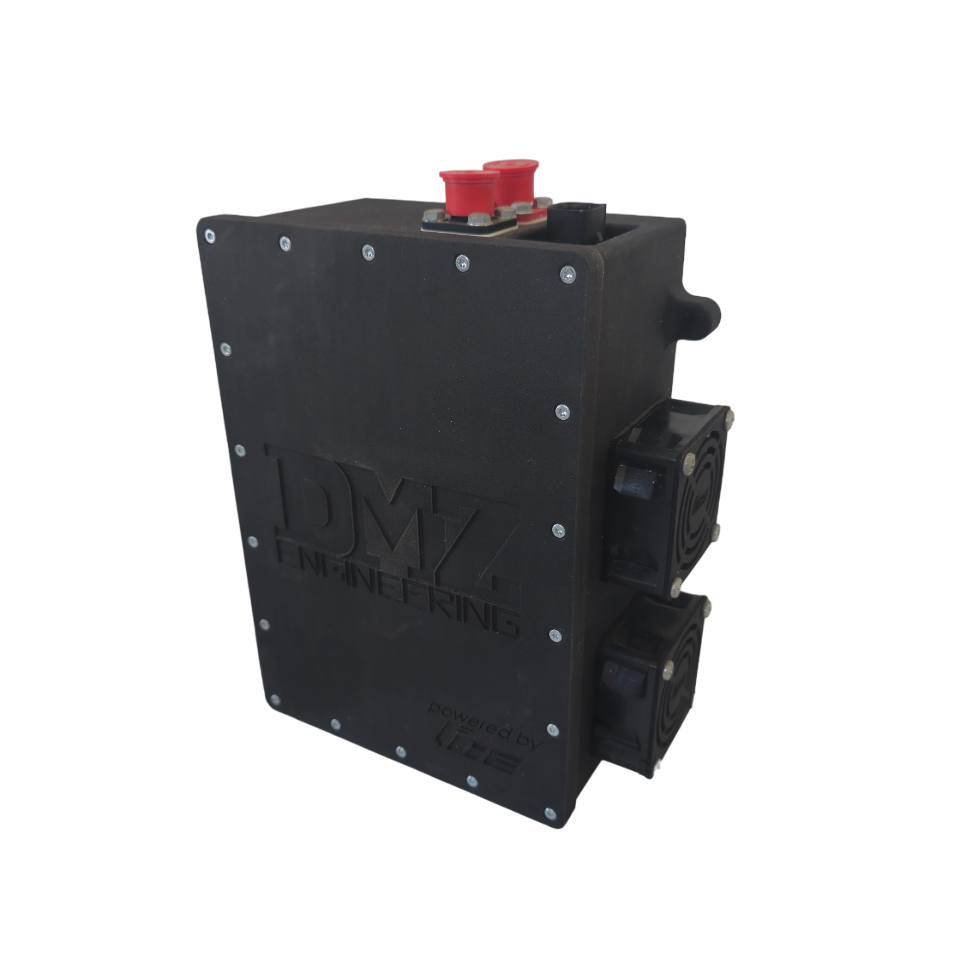

E-Booster

In collaboration with the innovative startup Fast Charge Engineering, DMZ Engineering is developing a fully electric system to enhance turbo engine supercharging, eliminating turbo lag and increasing the system’s performance at low engine speeds. The system will be managed by a dedicated control unit communicating via CAN bus protocol with the engine ECU and powered by a lithium-ion battery pack with a nominal voltage of 48V and a peak power of 5.5 kWp. The system is air-cooled and housed in a case made with MJF technology. The system is modular and allows scaling the component’s autonomy according to the user’s requirements.